ZF 9HP

In the remote reaches of Cobo Hall one can find a number of vendors tucked away at the NAIAS. ZF was there with a display of its wares and

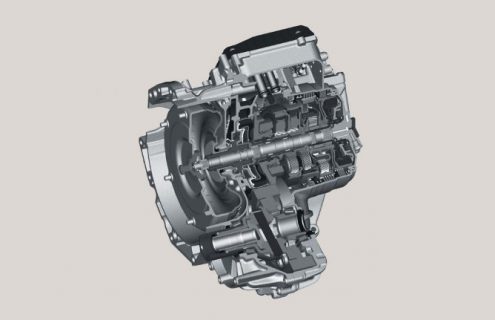

front and center was a cutaway of the 9HP, nine speed automatic gearbox for FWD applications.In the fight for ever greater fuel economy (and lower carbon dioxide emissions), compact, efficient transmissions with a wide gear spread, from low to high, will be in great demand. The 9HP fits the bill. By adding three speeds on top of an existing 6 speed FWD gearbox, the 9HP can take advantage of a steeper first gear, the intermediate ranges can be brought closer together (less RPM drop between shifts), and it can still deliver a couple of extra overdrive ratios at the top to further squeeze additional fuel mileage out of the fuel load.

One of the enablers of the 9HP was the first ever use of interlocking dog clutches in an automatic gearbox. The use of dog clutches save space and enhance efficiency when compared to the use of multi-disc shift elements used in other transmissions. Using four simple gearsets, four dog clutches and two brake bands, the nine forward speeds and reverse can be selected. The gearbox is start/stop capable without requiring an additional fluid pump. The torque converter incorporates a multi-level vibration damper which reduces NVH, especially helpful when used with small engines. In addition, the gearbox supports all wheel drive applications. In addition the gearbox is available in two torque capacities, one good for up to 280 NM of torque and one good up to 480 NM.

I have one request though. That is for someone to couple the 9HP with a two speed final drive that allows the four top (overdrive) gears (sixth through ninth) to be doubled, making it, effectively, a 13 speed gearbox. Then all you have to do is equip the car with a really good diesel truck air horn.

FWD

News of a FWD BMW has reared its head again, and it is due to be be unveiled sometime this year according to the latest rumors. There is also be a lot of conjecture as to why, and some pretty interesting guesses as to how the thing will be built.

This is what we know. BMW has made provision for a flexible firewall location in its latest ‘platform matrix’ for smaller cars. That means given a five link rear axle, a set of MacPherson struts up front and other components (sound systems, seats, HVAC, electronics, ABS, etc) you can build a FWD version of a 1er. The FWD BMW won’t be built using the existing Mini chassis. It will be built using a variation of the BMW smaller car matrix.

While this should be BMW’s first foray into a production FWD car, it certainly isn’t BMW’s first attempt at building and evaluating a FWD vehicle. Before BMW bought Dixi in 1928, they had a series of FWD cars designed and several prototypes running. It started in 1925 with the F50 (Fahrgestell, Projekt-Nr. 50) a V8 powered FWD car. That was followed by a transverse four cylinder FWD prototype, F 55, in 1927. A picture that many have seen is the F 55 prototype mule driving with a snowy Bavarian landscape as a backdrop. And in 1928, prior to the acquisition of Dixi, the F 65 was proposed with a six cylinder motor and FWD. In that era, constant velocity joints were just under development. And it was a production quality CV joint that enables FWD. Regardless, Dixi was

purchased and along with it the automobile works in Eisenach, as well as the license to build the Austin 7.Then after World War II, BMW proposed another FWD car, the 513, utilizing a two cylinder boxer motorrad engine. It was a pretty little car with it’s air cooled engine well in front of the axle, not unlike a contemporary French Panhard. But cash was hard to come by, and BMW settled on producing the Baroque Angels instead.

So it is no surprise, in an age when governments are dictating increasingly strict tailpipe emissions and fuel consumption, across a maker’s fleet, that FWD resurfaces at BMW. As mentioned before, use the three cylinder (the new 500 cc per cylinder architecture) gas or diesel motor with the ZF 9HP and place that drivetrain in an A or B class body. You instantly improve your fleet MPG and carbon dioxide emissions.

It would be nice if they restrict the engine choices to tuned variations of the three cylinders, and whatever else is done, don’t offer a variant of the 3 series in FWD (a BMW S60 – perish the thought!). And, to placate the purists, resist the urge to M-cessorize the FWD offerings.

Looms

I stumbled across a YouTube video of the manufacturing process for Time Bicycles, a French maker of high end carbon fiber bikes. What caught my attention is that they’re using a Resin Transfer Molding process, not unlike the process BMW will (is) using to construct its passenger cells for the i3 and i8.

But the initial moments of the video show the process of weaving individual strands of fiber into cloth that can be formed into bicycle parts. The process of weaving fibers into cloth is one of the oldest human manufacturing processes. And the start of the industrial age was the mechanization of the weaving process using water as an energy source. Eventually the weaving process was automated thanks to the Jacquard loom.

It’s coming full circle, BMW is having fibers spun with hydroelectric power at the Moses Lake facility. What was old is new again. Gives one hope.

Author: Hugo Becker

Source: http://www.bmwblog.com/2012/01/27/the-s ... and-looms/