The second model in the U.S. 5 Series Gran Turismo line-up is due to be unveiled at the Detroit Auto Show in less than two weeks. The launch of the BMW 535i GT also coincides with the introduction of a new BMW engine, internal codename: N55.

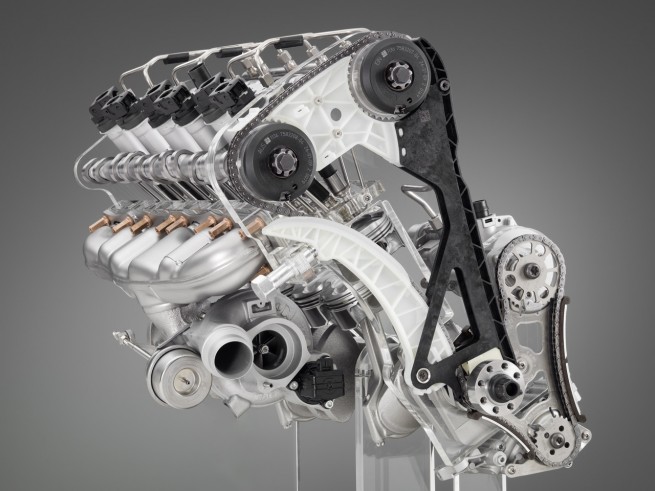

The new BMW Power Turbo uses a single twin scroll turbo instead of twin turbochargers as the N54 engine. The 2,979cc six-cylinder powerplant features for the first time High Precision Injection and variable VALVETRONIC valve management combined with the single twin-scroll turbocharger.

Even though BMW has not yet confirmed our suspicions, we believe the single turbocharger used in the 5 Series GT is the same as those fitted to the new 4.4 liter V8 engine in the X5M/X6M. Power and torque is similar to the twin turbo engine – 225 kW/306 hp at a speed of 5,800 rpm- but the 400Nm/295 lb-ft peak torque kicks in 1,000 rpm earlier at 1,200 rpm.

Compared to the BMW turbo engine already well-known in the 335i, 535i and other models, the N55 engine offers even greater fuel economy combined with optimized CO2 management. The power unit of the BMW 535i Gran Turismo is the first turbocharged engine to feature a map-controlled oil pump which, taking up less energy, makes a further contribution to motoring efficiency.

Since the full details on BMW’s N55 twin-scroll engine are yet to be fully revealed, we believe you will find the article below quite interesting. Modified goes into some of the details related to a Twin-Scroll Turbo System design.

Twin-scroll turbo system design addresses many of the shortcomings of single-scroll turbo systems by separating those cylinders whose exhaust gas pulses interfere with each other. Similar in concept to pairing cylinders on race headers for normally aspirated engines, twin-scroll design pairs cylinders to one side of the turbine inlet such that the kinetic energy from the exhaust gases is recovered more efficiently by the turbine. For example, if a four-cylinder engine’s firing sequence is 1-3-4-2, cylinder 1 is ending its expansion stroke and opening its exhaust valves while cylinder 2 still has its exhaust valves open (while in its overlap period, where both the intake and exhaust valves are partially open at the same time). In a single-scroll or undivided manifold, the exhaust gas pressure pulse from cylinder 1 is therefore going to interfere with cylinder 2’s ability to expel its exhaust gases, rather than delivering it undisturbed to the turbo’s turbine the way a twin-scroll system allows.

The result of the superior scavenging effect from a twin-scroll design is better pressure distribution in the exhaust ports and more efficient delivery of exhaust gas energy to the turbocharger’s turbine. This in turn allows greater valve overlap, resulting in an improved quality and quantity of the air charge entering each cylinder. In fact, with more valve overlap, the scavenging effect of the exhaust flow can literally draw more air in on the intake side while drawing out the last of the low-pressure exhaust gases, helping pack each cylinder with a denser and purer air charge. And as we all know, a denser and purer air charge means stronger combustion and more power, and more power is good!

But the benefits of twin-scroll design don’t end there. With its greater volumetric efficiency and stronger scavenging effect, higher ignition delay can be used, which helps keep peak temperature in the cylinders down. Since cooler cylinder temperatures and lower exhaust gas temperatures allows for a leaner air/fuel ratio, twin-scroll turbo design has been shown to increase turbine efficiency by 7-8 percent and result in fuel efficiency improvements as high as 5 percent.

Author: Horatiu B.

Source: http://www.bmwblog.com/2010/01/02/twin- ... explained/