The Spun Bearing: 500cc Combustion Chamber, Wave Disc Generator, and Leather vs Cloth

The 500cc Combustion Chamber

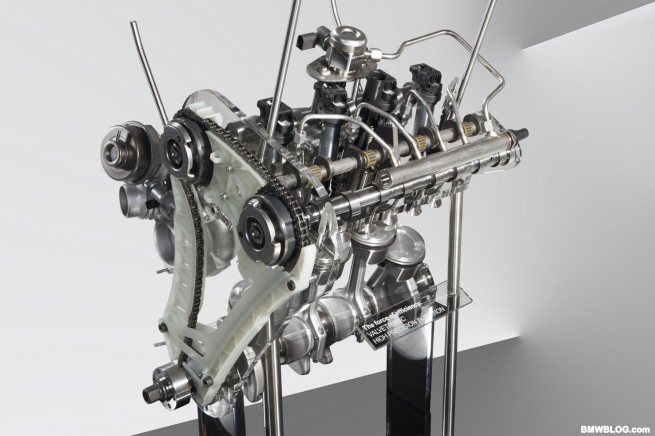

BMW is migrating towards a common combustion chamber for its upcoming 3, 4, and 6 cylinder engines. BMWBLOG covered Innovation Day last year and reported on this engine architecture in April of 2011.

One of the prime benefits of going to a common combustion chamber (and valvetrain) is that the physical properties of the fuel burn are the same from engine to engine (for gas and again for diesel). With the advent of direct injection, variable valve timing, and Valvetronic –variable valve lift, the control of the combustion process is more complicated (and the combustion process itself is much more efficient) than a few decades ago.

Unfortunately the whole process of burning fuel in an engine currently is controlled by lines and lines of code in the Engine Control Unit (ECU). And squeezing every last gram of efficiency out of a quantity of fuel by tweaking code requires a lot more engineering effort than fiddling with carburetor jets. And it’s the promise of reducing engineering effort across a line of engines that is a big benefit of going to a common combustion chamber.

One of the most precious commodities at BMW is engineering. This isn’t a huge car company that can devout engineers to small projects with minimal return on investment. So going to a common combustion chamber makes sense for them.

Of course if the code is wrong and sneaks into production, it will affect a lot of engines. But counter-balancing that is the fact that there is only one chamber that has to be developed, and any gains in one are gains in all.

Left out of the equation at the Innovation Day discussion was whether the V8 and V12 engines would go to the common combustion chamber. That would mean a new generation of V8s and V12s would be developed. BMW did say, when asked, that the V8 and V12 would still be built, but there was no mention as to whether or not new versions would be developed.

Left unsaid about optimizing the engineering effort is what are they freeing up engineering resources to do. I think we know that a lot of engineering effort is being made on providing e-mobility. And that may be the biggest benefit, from BMW’s perspective, of the common combustion chamber.

Wave Disc Generator

The current best IC gasoline engines are about 25% efficient. That means for every four liters of fuel consumed, one actually is converted to work, while the other three go to creating heat. And we may have reached the peak (or are near the peak) of development for piston engines.

Every once and awhile an inventor will come up with some scheme that promises to repeal the laws of physics, ala the 200 MPG carburetor. Most schemes for burning fuel in a combustion chamber have been tried already (with varying degrees of success, see Sterling orbital engines, or Wankel rotary engines). But with improvements in electronics and metallurgy, some designs that are decades old are being revived.

One interesting piece of technology is the wave disc generator. It uses shock waves to create combustion in an air/fuel mixture. The pulse jet was the first analogy that popped into mind. The pulse jet was used in German V1 ‘rockets’ in World War II and by Lennox in furnaces in the 1990s. The pulse jet made an incredibly efficient furnace (and an interesting flying machine – as long as you weren’t on the receiving end), but it was thrust and heat – no mechanical motion.

The wave disc generator utilizes a series of waveform chambers in a spinning disc. It is claimed to be 60% efficient which beats a piston engine by a factor of 2.4. The problem is, how much torque can it produce (think rotary) and how big does it have to be before it becomes

useful. If it can produce power in a small package, the range extenders for plug-in hybrids may be in for an upgrade.Leather vs Cloth

Sometime in the last half a century in the US, leather replaced cloth as the premium material for seats in the interiors of cars. It used to be that leather was allocated to the driver and footman, who sat at the front of the conveyance, usually exposed to the elements, while the passengers sat in brocaded cloth upholstery in the enclosed compartment separated from the hoi polloi.

But then, sometime in the 1960s or 1970s, leather became synonymous with luxury. I’m still not sure how that happened. I suspect it may have something to do with vinyl being the ubiquitous seat covering for cars in the 1950s on. (And there were some pretty hideous implementations of vinyl – including metallic gold, turquoise, and olive green.) But that’s just a guess.

Cloth doesn’t have the same stigma in other markets that it does in the US. And quite frankly I’d rather have the comfort of a premium cloth than the discomfort of a premium leather. So it’s time for a poll: Given

a choice would you select cloth or leather – if the price was the same. And, if you have any guesses as to why leather replaced cloth as a premium seating surface please share them in the comments.Note: There is a poll embedded within this post, please visit the site to participate in this post's poll.

Author: Hugo Becker

Source: http://www.bmwblog.com/2012/02/03/the-s ... nlucky-13/